Overview

BLS 783 (65447-77-0 & 70624-18-9) is a synergistic blend of the hindered amine light stabilizers BLS 1622 and BLS 1944. The product is highly effective to improve the light stability of polyethylene (HDPE, LLDPE, LDPE) thick section parts, films, and tapes as well as polypropylene fibers and films. BLS 783 is non-discoloring, has good compatibility with polyolefin substrates, is highly resistant to extraction, and is FDA-cleared for use in many types of polyolefins for indirect food contact applications.

Chemistry

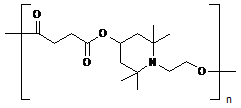

Chemical Names: BLS 1622: Butanedioic acid, dimethyl ester, polymer with

4-hydroxy-2,2,6,6-tetramethyl-1-piperidine ethanol

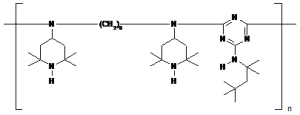

BLS 1944: 1,6-Hexanediamine, N,N’-bis

(2,2,6,6-tetramethyl-4 piperidinyl)-, polymer with

2,4,6-trichloro-1,3,5-triazine, reaction products with

2,4,4-trimethyl-2-pentanamine

CAS Numbers: BLS 1622: 65447-77-0

BLS 1944: 70624-18-9

Chemical Structure:

BLS 1622 BLS 1944

Typical Properties

Product Form: Solid

Melting Range: BLS 1622: 110 – 125oC

BLS 1944: 50 – 70oC

Molecular Weight: BLS 1622: Mn > 2500 g/mol

BLS 1944: Mn > 2500 g/mol

Applications

BLS 783 is a synergistic blend of polymeric hindered amine light stabilizers (HALS) developed for use in polyolefins. Recommended applications include polyethylene (HDPE, LLDPE, LDPE) moldings, films, and tapes, olefin copolymer (EVA) films, and polypropylene fibers and films.

Advantages

- Synergy between the components provides excellent light stability to PE molded parts, films, and tapes as well as to PP fibers and films

- Improves the thermal oxidative stability of polyolefins at moderate temperatures

- Excellent compatibility with polyolefins, resistant to extraction and migration

- Low volatility

- FDA-cleared for use in many polyolefins

- Convenient and easy to dose, low-dusting, pastille product form

Guidelines for Use

Typical recommended loading concentrations range between 0.1% and 1%. The use of BLS 783 in combination with a UV absorber such as BLS 1326 or BLS 531 is recommended in some unpigmented applications to improve retention of physical properties after weathering and also in formulations containing organic pigments to improve lightfastness and reduce color changes after weathering. The exact formulation to be used is dependent on the substrate, performance requirements, and other factors, and should be determined by the user based on testing to simulate actual conditions of use. Please contact Mayzo for specific recommendations.

Storage

This product may be stored up to two years in a sealed container. Containers should be kept tightly closed when not in use and stored in a cool, dry place.

Safety

Please consult the Safety Data Sheet (SDS) prior to handling or using this product.

FDA Regulations

The components of BLS 783 have been cleared for use in many polyolefins under 21 CFR §178.2010. Please contact your Mayzo representative for complete details, including restrictions of use.