Case Studies

Benetex® Optical Brighteners Case Study

Benetex® Optical Brighteners: optimized to improve customer manufacturing efficiency.

- Benetex OB Plus – ultra fine powder

Mayzo has a family of Optical Brighteners (OB) for use in adhesives, coatings, inks and

sealants. Optical Brighteners are used:

- To increase whitening/brightening of white or clear coatings, sealants and inks

- As a tracer to QC coating thickness of adhesives and coatings

- To provide a fluorescent effect or security feature on labels

Mayzo Custom Solutions Application Example:

Optical brightener typically needs to be milled in order to disperse the product more easily during manufacturing. Mayzo provides this milling service under tight quality control to help ensure that customer’s achieve process efficiency. Customers can save 8-24 hours, by not having to mill. This represents a huge savings through increased productivity. Also, their screen printing customers’ need a fine particle size to prevent screen blockage.

Therefore, Mayzo’s Benetex OB Plus ultra-fine particle size can offer our customer’s customer, the screen printer, a benefit in productivity by decreasing screen cleaning.

Summary of Benefits of Benetex OB Plus:

- Reduction in processing time – no need to mill product

- More uniform coverage in the final product

- A benefit to our customers’ customer in increased productivity due to less maintenance downtime

BNX 1225 TPR and BNX 5010 TPR Case Study

BNX® 1225 TPR and BNX 5010 TPR: optimized to improve customer manufacturing efficiency.

- BNX 1225 TPR – Pelletized Antioxidant Concentrate in SIS

- BNX 5010 TPR – Pelletized Antioxidant Concentrate in SIS

Mayzo has developed a family of pelletized antioxidant concentrates in SIS (styreneisoprene-styrene) thermoplastic elastomers for use in hot melt pressure sensitive adhesives using single or twin screw extrusion. TPR concentrates are:

- Highly loaded pre-dispersed uniform pellets of antioxidants in SIS

- Excellent heat and oxidation resistant stabilizers

- Free flowing and dust free for accurate dosing and improved hygiene

Mayzo Custom Solutions Application Example:

Antioxidants typically need to be added in very low concentrations and evenly dispersed throughout the product to be effective. Feeding neat additives at low target concentrations has significant potential downsides. The finished product can be off-spec due to the additive not being at the correct final concentration (too high or low) and/or there could be excess cost due to over dosing of the additive.

The TPR concentrate provides high melt resistance with non-bridging therefore decreasing variability and increasing processing efficiencies. Mayzo’s TPR concentrates can be used to achieve a uniform dispersion of the antioxidant in the adhesive.

Summary of Benefits of BNX 1225 TPR and BNX 5010 TPR:

- Accurate dispensing in loss-in-weight feeders (i.e. K-TRON®)

- Increased processing efficiency

- Minimize feeding issues

- Improved hygiene

- Low volatility

- Excellent compatibility with styrenic polymers, engineering plastics, polyurethanes and

PVC - FDA cleared for use in adhesive

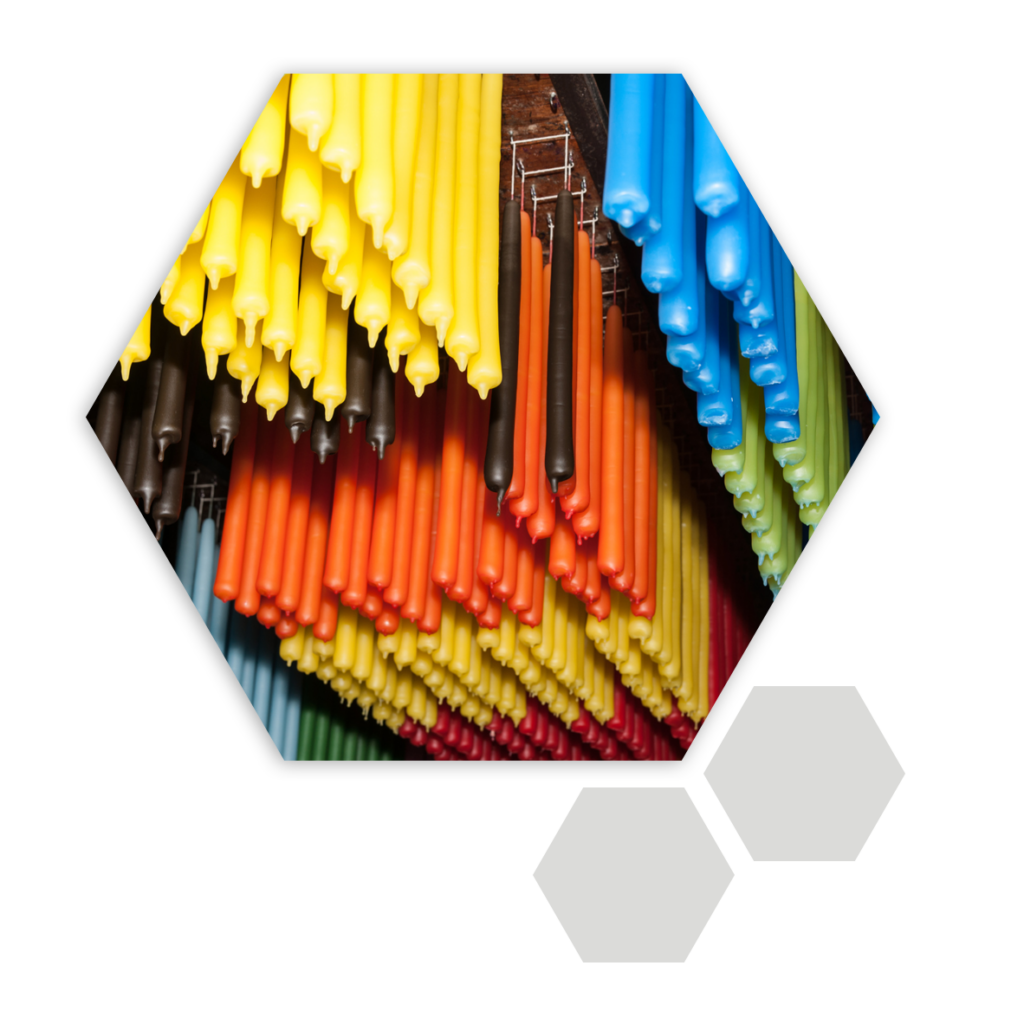

Evolution of Stabilizers for Candles

Butylated Hydroxytoluene (BHT) is a common antioxidant used to stabilize wax

Typically added at 50 to 100 ppm level by wax manufacturers

BHT causes color changes by a reaction which creates an unstable color species

Discoloration can occur in packaging prior to light exposure

Can be antagonistic with Hindered Amine Light Stabilizers (HALS)

Evolution of Stabilizers for Candles

Benzophenone and benzotriazole UV absorbers were introduced to the candle industry in the late 1980s and early 1990’s to protect formulations with complex fragrance chemistry and dyes that are not light stable

The primary UV absorbers used in candle formulations are UV-5411, UV-328 and UV-531

In the late 1990’s and early 2000’s, Hindered Amine Light Stabilizers (HALS) radical scavengers were introduced to the candle industry

Redshifted benzotriazole UV absorbers with high molar efficiency were pursued but did not gain traction

For more information on Stabilizers, click the link below

Stabilizer Technologies and Their Functionality in Candle Formulations

Mayzo’s Polypropylene Thermoforming Customers Use MPM 2000 “Beta Nucleating Technology” to Support Sustainability Goals

If you mold or sell polypropylene (PP) containers such as yogurts, wipes, and food packaging and want to meet your sustainability goals, Mayzo’s Beta Nucleating Technology is a great option to add to your formulations.

Mayzo’s customers that have incorporated its MPM 2000 “Beta Nucleating Technology” into their thermoforming production lines realize these four key benefits:

- Achieve a down-weighting rate of at least 15% without sacrificing the physical properties and rigidity of the container. Hence, molders saw a reduction in the amount of polypropylene (PP) resin necessary to produce the same number of units.

- Realize a productivity improvement of up to 25%. This faster cycle rate with the use of the Beta Technology lowered individual container and energy costs.

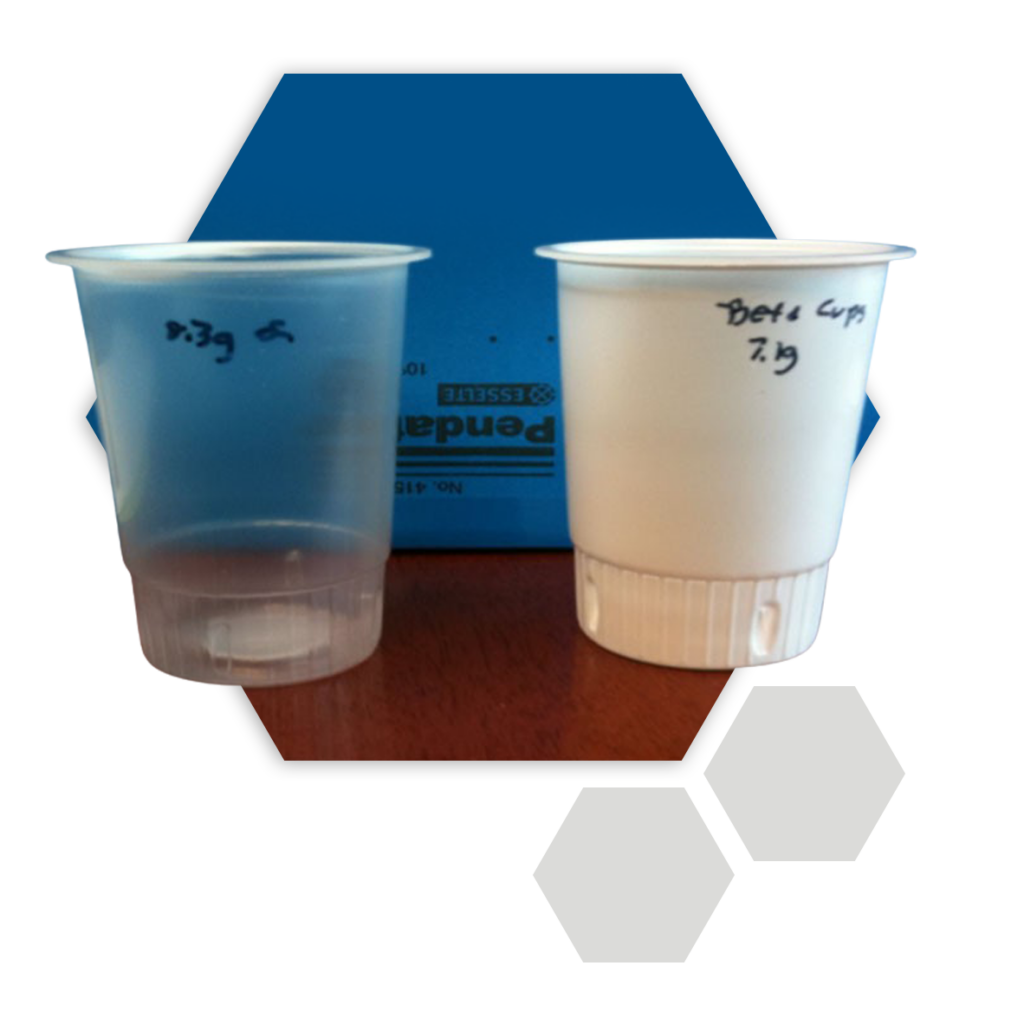

- Ability to mold a white container without using the white pigment (TiO2). Not only does this meet new European regulations, but they saw an increase in the value of the polypropylene recycled material made from these containers. Non-pigmented recycled plastics have a higher market value and offer more comprehensive range of practical applications for the recycled resin.

- Combining these three benefits Mayzo’s customers offer end-users a more sustainable / greener container compared to those produced without the MPM 2000 “Beta Nucleating Technology”.

Contact Mayzo to learn more about our “Beta Nucleating Technology” by phone at 1-800-449-9068 or at our contact form.

Mayzo’s Polypropylene “Beta Technology” helps Thermoformers overcome Cost, Supply and Capacity Challenges

As polypropylene resin prices continue to fluctuate, thermoforming plastics manufacturers are looking for new cost-effective and sustainable solutions. Increasingly, thermoformers are realizing the advantages of Mayzo’s proprietary “Beta Technology” – a beta nucleating masterbatch which enables processors to use less resin while producing more product, faster. These benefits help thermoformers meet today’s challenges, including rising resin costs, transportation difficulties, supply disruptions and sustainability imperatives.

“Thermoforming customers are achieving two substantial advantages through the use of Mayzo’s Beta Technology,” stated Dr. Philip Jacoby, a renowned polypropylene expert and retired VP of Technology at Mayzo. “First, they are achieving down-weighting of at least 15%. That means less polypropylene resin is required to produce the same amount of end product. Second, they are realizing a productivity improvement of up to 25%. This faster cycle rate is proving especially valuable for Mayzo’s customers in the rigid food packaging business, who also appreciate the masterbatch’s broad food contact approvals.”

Photo Caption: White cup on the right was produced using Mayzo’s “Beta Technology”, with No TiO2.

“Other benefits include a dramatic reduction or even elimination of TiO2 pigments used to make white containers” explains Jacoby. This is a boon to processors who are committed to meeting sustainability goals. By eliminating white pigments from the product, the Post Consumer Resin (PCR) resin recovered has higher value.

“Interest in our Beta Technology is significantly increasing,” said Ben Milazzo, Chairman of Mayzo Inc. “The positive results achieved through use of this masterbatch are compelling. With the recent industry capacity constraints and escalating PP resin pricing, more and more plastics manufacturers are eager to incorporate Mayzo’s Beta Technology into their production lines.”

Mayzo provides specialty chemical additive solutions on a global scale in a wide range of markets. Since 1986, customers have relied on the Mayzo team for their ingenuity, responsiveness, and extraordinary service culture.

To learn more contact us at 1-800-449-9068 or by email at sales@mayzo.com