Overview

BLS 1944 (70624-18-9 -US or 71878-19-8 – EU) is a high molecular weight hindered amine light stabilizer. It provides outstanding light stability to many polymers and it also provides long-term stability to polyolefins by a radical trapping mechanism similar to that of hindered phenols. Significant levels of stabilization are achieved at relatively low concentrations. Because of its polymeric structure, BLS 1944 has a very low volatility (even at high temperatures), low extractability and low migration rate from polymeric substrates. When compounded, BLS 1944 imparts no negative effects on a substrate’s initial color, its low dust, free-flowing form makes it exceptionally convenient to handle.

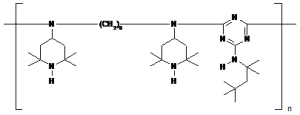

Chemistry

Chemical Name: Poly[[6-[(1,1,3,3,-tetramethylbutyl)amino –s-triazine-2,4-diyl]

[2,2,6,6-tetramethyl-4-piperidyl)imino]]hexamethylylene[(2,2,6,6-tetramethyl-

4-piperidyl)imino]]

CAS Number: 70624-18-9 (US) or 71878-19-8 (EU)

Chemical Structure:

Typical Properties

Product Form: Solid Melting Point: 100-135oC

Molecular Weight: Mn > 2,500

Applications

BLS 1944 is a polymeric hindered amine light stabilizer offering excellent protection against ultraviolet degradation. BLS 1944 areas of application include polyolefins (polypropylene, polyethylene), olefin copolymers such as EVA as well as blends of polypropylene with elastomers. In addition, BLS 1944 can be highly effective in polyacetals polyamides, polyurethanes, flexible and rigid PVC, as well as PVC blends and in some styrenic elastomer and adhesive specialty applications.

Advantages

- Free-flowing low dust

- Excellent resistance to extraction

- Excellent long-term light stability in tick sections, specifically polyethylene applications

- Excellent long-term light stability, particularly in thin articles like fibers and films

- Low volatility

- FDA clearances in polypropylene and polyethylene

- Ease of compatibility with other stabilizers

Guidelines for Use

The recommended loading concentrations in thick sections of HDPE, LLDPE, LDPE and PP range between 0.05% and 0.6% depending on substrate, processing conditions, and long-term stability requirements. Concentration levels of BLS 1944 in films like LLDPE and LDPE range from 0.1% to 1%, and in tapes like PP and HDPE, BLS 1944 concentrations range between 0.2% and 0.8%. Concentrations levels of BLS 1944 in fibers of PP range between 0.1% and 1.0%. The presence of a UV absorber like BLS 1328 is recommended in unpigmented or slightly pigmented articles or or to improve lightfastness of certain organic pigments. The exact formulation to be used is dependent on the substrate, performance requirements, and other factors, and should be determined by the user based on testing to simulate actual conditions of use. Please contact Mayzo for specific recommendations.

Storage

This product may be stored up to two years in a sealed container. Containers should be kept tightly closed when not in use and stored in a cool, dry place.

Safety

Please consult the Safety Data Sheet (SDS) prior to handling or using this product.

FDA Regulations

BLS 1944 has been cleared for use in polypropylene and polyethylene under 21 CFR §178.2010. Please contact your Mayzo representative for complete details, including restrictions of use.

Chimassorb 944