Overview

BNX 1035 ( 41484-35-9) is a multifunctional antioxidant containing both hindered phenolic and thioether moieties. The product is widely used for the process stabilization of cross-linked polyethylene wire and cable resins and as an antioxidant in lubricants.

Chemistry

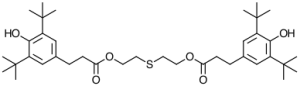

Chemical Name: Benzenepropanoic acid, 3,5−bis(1,1−dimethylethyl)−4− hydroxy−, 1,

1’−(thiodi−2,1−ethanediyl) ester

CAS Number: 41484-35-9

Chemical Structure

Typical Properties

Product Form: Solid

Melting Point: 63oC (minimum)

Molecular Weight: 642.9 g/mol

Applications

BNX 1035 is widely used for the process stabilization of polyethylene wire and cable resin applications, eliminating the concern over micro-contaminants that can affect the insulation properties of the wire, and it also prevents premature gel formation of chemically cross-linked polyethylene during extrusion compounding. BNX 1035 also provides efficient processing stabilization and long-term thermal stability with excellent system compatibility and low color in styrenic polymers, polypropylene, polyurethanes, polyesters, segmented block copolymers, other rubber modified polymers, and elastomers (including EPDM, SBR, carboxylated SBR latex, and polybutadiene and polyisopropene rubber).

It also provides excellent stabilization in petroleumbased products, including lubricants (such as turbine oils) petrolatum, and higher poly alpha-olefins.

Advantages

- Provides excellent stability during high temperature processing and long term heat aging

- Most widely used antioxidant for PE and XLPE wire and cable resins

- Highly compatible with a wide range of organic substrates

- Non-staining and non-discoloring

- Odorless and tasteless

- Low volatility

- FDA clearances in adhesives, hydrocarbon resins, rubber products, and lubricants

- High level of compatibility with carbon black and other stabilizers

Guidelines for Use

The recommended loading concentrations range between 0.2% and 0.3% in polyethylene and carbon black containing polymers, and between 0.3% and 0.4% in polyols. Combinations of BNX 1035 with other antioxidants such as phosphites and thioethers often show synergistic performance. BNX 1035 is also suitable for use in combination with light stabilizers, including hindered amine light stabilizers (HALS), UV absorbers, and benzoates. The exact formulation to be used is dependent on the substrate, performance requirements, and other factors, and should be determined by the user based on testing to simulate actual conditions of use. Please contact Mayzo for specific recommendations.

Storage

This product may be stored up to two years in a sealed container. Containers should be kept tightly closed when not in use and stored in a cool, dry place.

Safety

Please consult the Safety Data Sheet (SDS) prior to handling or using this product.

FDA Regulations

BNX 1035 is cleared for use in adhesives under 21 CFR §175.105; in pressure-sensitive adhesives, petroleum alicyclic hydrocarbon resins, and finished rubber products under 21 CFR §178.2010; and in lubricants under 21 CFR §178.3570. Please contact your Mayzo representative for complete details, including restrictions of use.